Heavy Equipment Monitoring & Asset Management

1. Background

1. Background

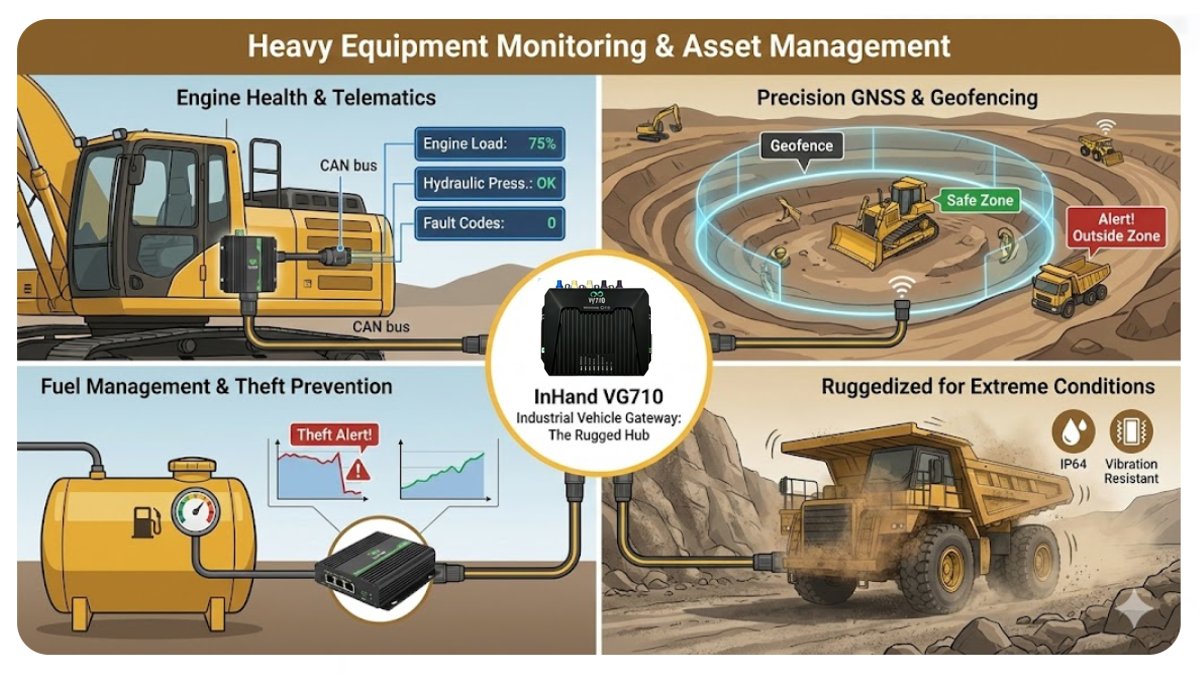

In large-scale construction sites and remote mining operations, heavy machinery such as excavators, bulldozers, and haul trucks are high-value assets operating in extreme environments. Fleet managers face challenges in monitoring engine health, preventing fuel theft, and ensuring that expensive equipment is used efficiently and stays within designated safety zones.

2. The Solution: InHand VG710 Industrial Vehicle Gateway

The InHand VG710 is installed in the cabin or engine compartment of heavy machinery to act as a ruggedized communication and data processing hub, connecting the vehicle’s internal systems to a remote management center via 5G/4G networks.

3. Key Implementation Features

Engine Health Monitoring (J1939/CAN Bus): The VG710 connects directly to the vehicle's CAN bus using the J1939 protocol. It reads critical telematics data such as engine load, coolant temperature, hydraulic pressure, and fault codes. This allows for "Condition-Based Maintenance," where parts are replaced only when needed, preventing catastrophic failures.

Fuel Management & Theft Prevention: By monitoring fuel levels in real-time and correlating them with engine activity, the VG710 can detect sudden fuel drops (potential theft) or abnormal consumption patterns, helping operators reduce operational costs.

High-Precision GNSS & Geofencing: Mining sites are often complex. The VG710 uses its high-precision GNSS to track equipment location. Managers can set "Geofences"; if a bulldozer leaves a authorized area or enters a dangerous blast zone, the gateway triggers an immediate alert via the cloud.

Ruggedized for Extreme Environments: Construction sites are dusty and vibrate intensely. The VG710’s IP64 rating protects it against dust and water splashes, while its MIL-STD-810G compliant vibration and shock resistance ensures it remains functional in the harshest terrains.

Wireless Sensor Integration (Bluetooth): The gateway can connect to wireless Bluetooth sensors for tire pressure monitoring (TPMS) or driver identification, reducing the need for complex wiring in the vehicle.

4. Hardware Advantages for Heavy Industry

Wide Temperature Range: Operates reliably from -40°C to +70°C, essential for outdoor work in desert or arctic mining sites.

Edge Computing: Using Python, the gateway can locally filter noise from sensor data, only sending critical alerts to the cloud to save on satellite or cellular data costs in remote areas.

Dual SIM Backup: Ensures that if one mobile network has poor coverage in a deep pit or remote site, the device can automatically switch to a second provider.

5. Results and Benefits

Minimized Downtime: Predictive maintenance reduces unexpected breakdowns by up to 25%.

Asset Security: Real-time tracking and geofencing provide 24/7 security for multi-million dollar equipment.

Operational Insight: Accurate data on "idle time" vs. "work time" allows managers to optimize fleet utilization and reduce wasted fuel.

Topic Participants

david.jing