Predictive Maintenance for Industrial Robotics

1. The Challenge

1. The Challenge

In modern automotive or electronics factories, industrial robots and CNC machines operate at high speeds. Even a minor mechanical failure can lead to expensive production downtime. Traditionally, monitoring these machines requires sending massive amounts of raw sensor data (vibration, temperature, and torque) to a central server, which often results in high latency and excessive bandwidth costs.

2. The EC312 Edge Solution

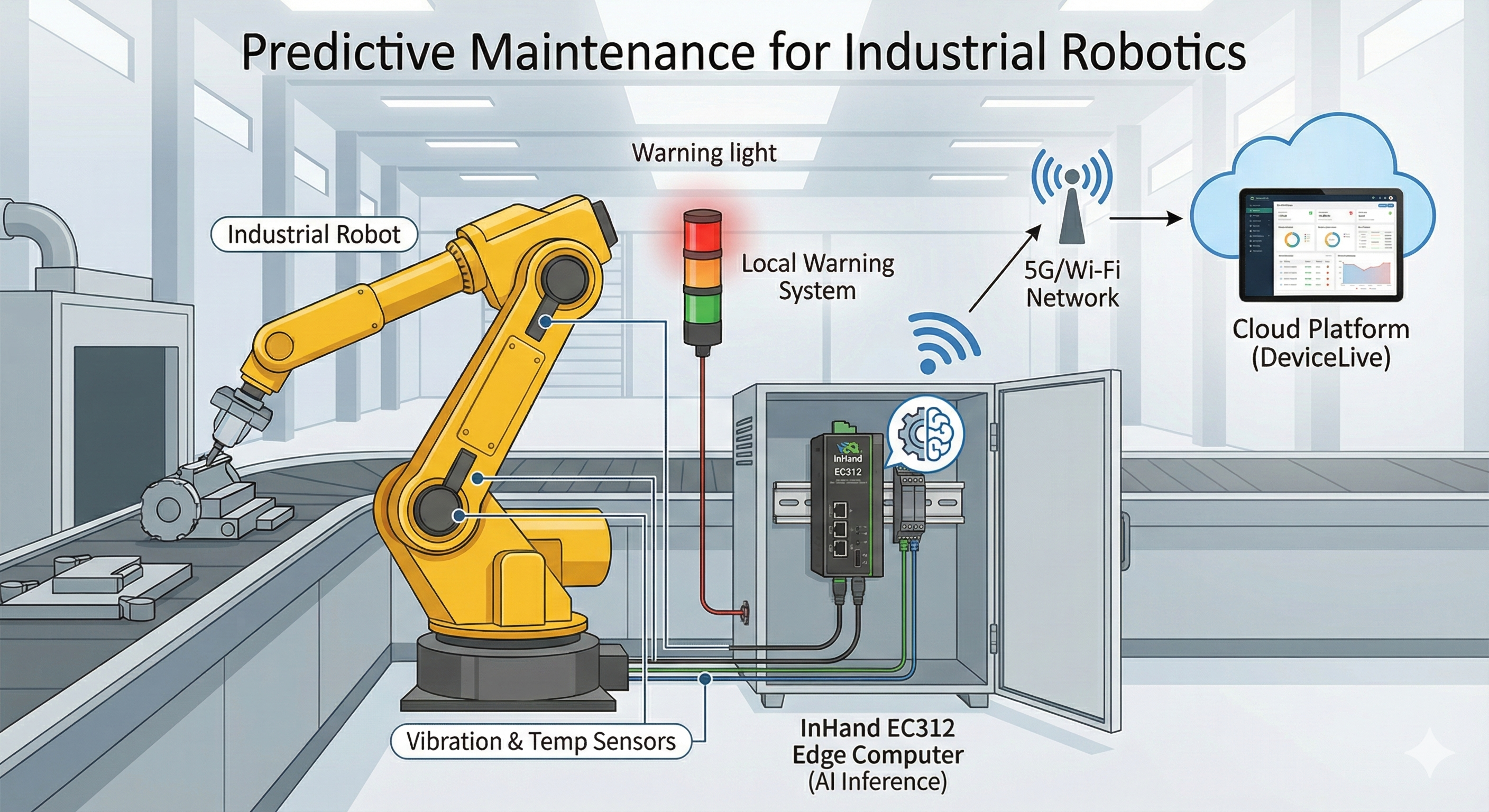

The EC312 acts as the localized "brain" for the production cell, processing data at the source to enable immediate response.

Data Integration: The EC312 connects directly to factory PLCs and motor controllers via its RS-485 serial ports or Ethernet interface.It supports industrial protocols such as Modbus TCP, OPC UA, and EtherNet/IP to ensure seamless communication with equipment from different vendors.

Local AI Inference: Leveraging its ARM Cortex-A53 processor and support for Docker containers, the EC312 can run lightweight machine learning models locally.These models analyze high-frequency vibration data to detect early signs of bearing wear or motor fatigue without relying on a cloud connection.

Real-time Control: Through the N44D expansion module, the EC312 provides 4x Digital Inputs (DI) and 4x Digital Outputs (DO).If an anomaly is detected, the EC312 can immediately trigger a local warning light or signal the PLC to safely slow down the machine.

Industrial Hardening: The fanless design and IP30 metal-plastic enclosure allow the EC312 to be mounted on a DIN-rail directly inside the machine’s control cabinet, where it can withstand industrial vibration and dust.

3. Security and Remote Management

Data Protection: Critical manufacturing algorithms are protected by the EC312’s hardware security features, including Secure Boot and the TPM 2.0 chip, which prevent unauthorized software from running on the device.

Cloud Connectivity: While processing occurs at the edge, the EC312 uses its 5G/4G cellular link or factory Wi-Fi to upload summarized health reports and maintenance logs to the DeviceLive platform.

Remote Maintenance: Engineers can use DeviceLive to remotely update the Docker-based analysis applications or access the device via VPN for remote troubleshooting, reducing the need for on-site technician visits.

4. Key Benefits

Reduced Latency: Millisecond-level anomaly detection enables faster equipment protection.

Reduced Latency: Millisecond-level anomaly detection enables faster equipment protection.

Bandwidth Savings: Only pre-processed results and alerts are sent to the cloud, significantly lowering data costs.

Maximum Uptime: Predictive alerts allow maintenance to be scheduled during planned shifts, preventing unexpected line stoppages.

Topic Participants

david.jing