Remote Pump Station Monitoring in Smart Water Systems

1. Problem Description

1. Problem Description

Municipal water departments often manage numerous pump stations distributed across wide geographic areas to ensure stable water pressure and effective wastewater drainage. Manual inspections of these stations are labor-intensive, and traditional monitoring systems often lack the intelligence to process data locally, leading to high cellular data costs and delayed responses to critical failures like pipe bursts or motor overheating.

2. The IG502 Solution

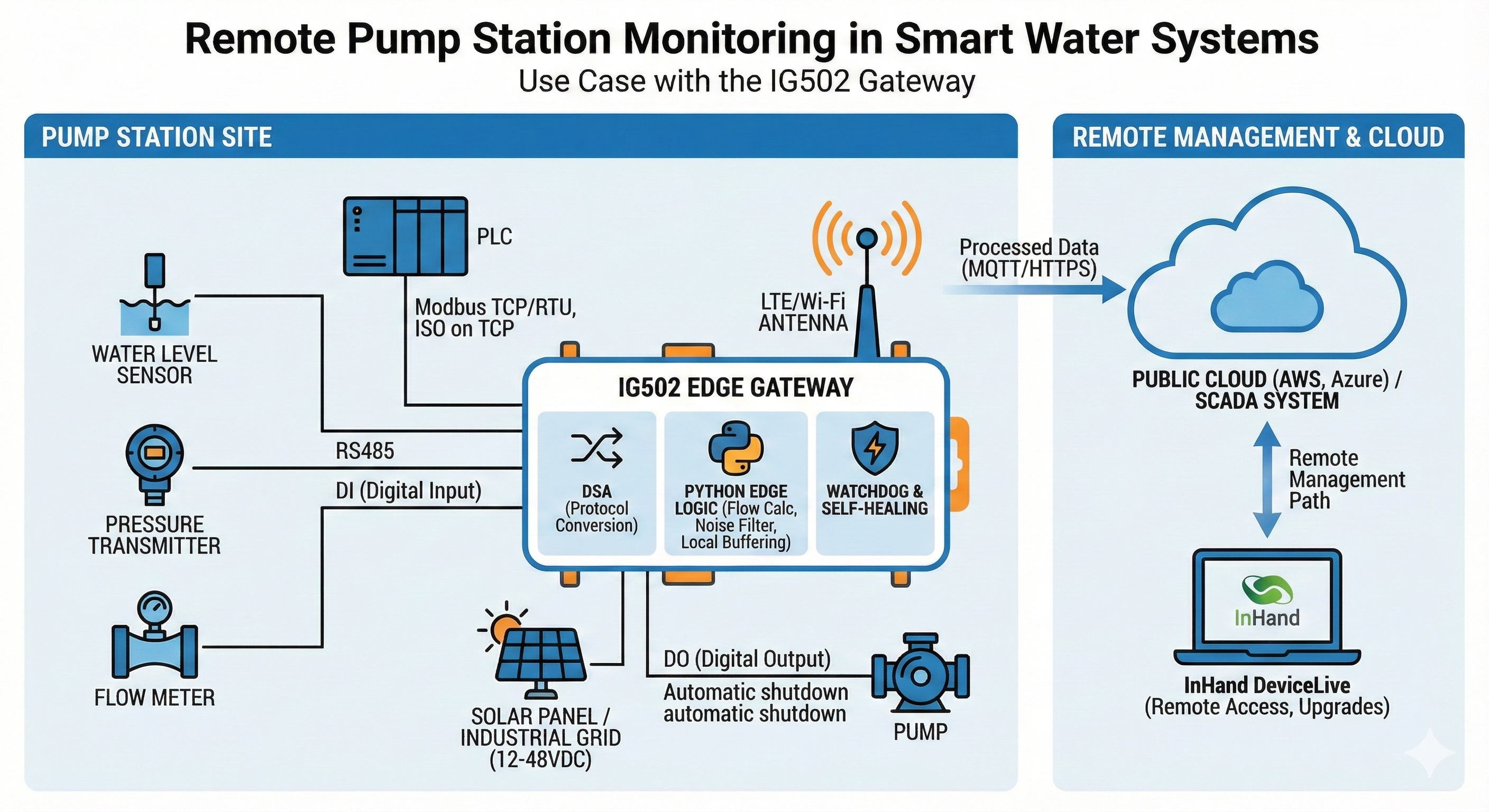

The IG502 acts as an intelligent edge node, providing a cost-effective and reliable way to digitize water management. By leveraging its rich interfaces and edge computing capabilities, the gateway transforms raw sensor data into actionable insights before sending it to the cloud.

Integrated Data Acquisition: The IG502 connects to water level sensors, pressure transmitters, and flow meters via RS485 or Digital Input (DI) ports.

Protocol Support: It uses the built-in DeviceSupervisor Agent (DSA) to communicate with on-site PLCs using protocols like Modbus TCP/RTU or ISO on TCP.

Edge Logic and Filtering: Engineers can deploy Python scripts to calculate real-time flow rates or set local logic to trigger the Digital Output (DO) to shut down a pump automatically if an emergency pressure threshold is reached.

Robust Wireless Link: In remote areas without wired internet, the IG502 provides stable 4G LTE or Wi-Fi connectivity with dual-SIM failover to ensure the management center never loses contact with the station

3. Implementation Steps

- Connectivity: On-site sensors are wired to the IG502's industrial terminal blocks, utilizing the 12-48VDC wide power input which is ideal for stations powered by solar or unstable industrial grids.

- Configuration: The administrator uses the web management interface to enable the Cellular network and configure the DSA for "zero-code" data collection from the pumps.

- Data Processing: A custom PythonApp is installed on the IG502 to filter out sensor noise and perform local data buffering in the 8GB eMMC storage during network outages.

- Cloud Integration: Processed data is reported to the municipal SCADA system or a public cloud like AWS using MQTT or HTTPS.

- Remote Maintenance: Technical support engineers use the InHand DeviceLive cloud service to remotely access the gateway, perform firmware upgrades, or check system logs without visiting the site.

4. System Value

- Operational Stability: The independent hardware watchdog and multi-level link detection ensure that the gateway self-heals from communication or software errors.

- Cost Efficiency: Local data processing reduces the volume of data sent over the cellular network, significantly lowering monthly operational expenses.

- Scalability: The Docker environment allows for the easy deployment of new management applications as the smart water network expands.

Topic Participants

david.jing