Smart Energy — Remote Wind Farm Monitoring & Predictive Maintenance

1. The Challenge

1. The Challenge

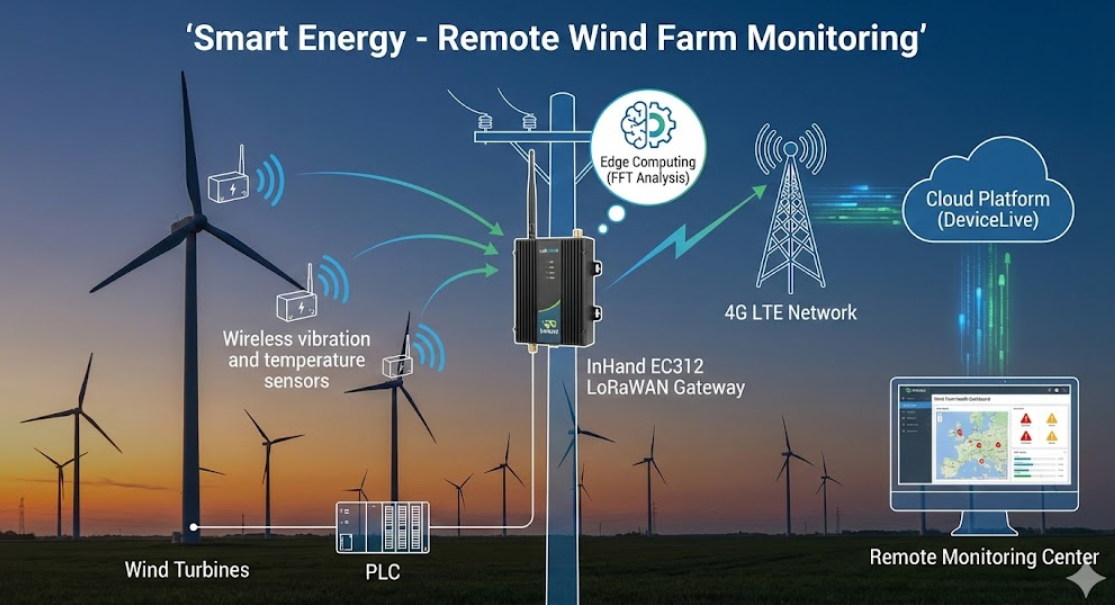

Wind turbines are often located in remote, offshore, or mountainous regions where installing wired communication cables is cost-prohibitive. Maintaining these assets is expensive, and operators need a way to monitor mechanical vibrations, nacelle temperatures, and blade integrity in real-time to prevent catastrophic failures. However, cellular signals may be inconsistent at the ground level among giant metal structures, and high-bandwidth solutions are often overkill for simple sensor data.

2. The EC312 LoRaWAN Solution

The EC312 LoRaWAN Gateway serves as the central intelligence hub for the wind farm's sensor network.

- Long-Range Wireless Coverage: Utilizing the Semtech SX1302 baseband chip, a single EC312 can cover a radius of up to 15 km (LOS), allowing one gateway to collect data from sensors mounted on dozens of turbines across the farm.

- Diverse Data Acquisition: The EC312 uses its Device Supervisor agent to collect performance data directly from the turbine’s PLC via Modbus TCP or OPC UA, while simultaneously receiving low-power LoRaWAN signals from wireless vibration and humidity sensors.

- Localized Edge Computing: Powered by an ARM Cortex-A53 @1.4GHz processor with 1GB RAM, the EC312 can run Docker containers locally to perform initial data filtering and FFT (Fast Fourier Transform) analysis on vibration data. This ensures only critical anomalies are transmitted, saving on cellular data costs.

- Uninterrupted Connectivity: To ensure data reaches the control center, the EC312 features multi-link redundancy, utilizing 4G LTE with dual SIM failover as the primary backhaul, with the ability to switch to satellite or Ethernet links if needed.

3. Industrial Reliability in Harsh Conditions

- Extreme Weather Resistance: The EC312 is built for industrial environments with an operating temperature range of -20°C to 70°C and a fanless, IP30 rated metal-plastic housing.

- Power Failure Resilience: Wind farm substations can experience power fluctuations. The EC312 includes a supercapacitor that provides 20 seconds of backup power, allowing the device to trigger a power-failure alarm and perform a safe shutdown to protect the 8GB eMMC storage.

- Hardware-Grade Security: Protection of critical energy infrastructure is managed by the EC312’s built-in TPM 2.0 chip and Secure Boot technology, preventing unauthorized firmware tampering.

4. Results and Benefits

- Reduced Downtime: Predictive maintenance alerts allow operators to schedule repairs before a component fails, potentially saving millions in emergency repair costs.

- Lower Operational Costs: The high node capacity (up to 2,000 nodes) and long range of the EC312 minimize the number of gateways required per site.

- Centralized Management: Through the DeviceLive cloud platform, technicians can remotely manage the EC312 fleet, deploy updated edge applications, and troubleshoot connectivity issues without visiting the remote site.

Topic Participants

david.jing