Smart Factory Machine Monitoring and Data Intelligence with IG502

1. Background and Challenges

1. Background and Challenges

Modern manufacturing facilities often struggle to integrate data from diverse legacy equipment and modern sensors

. Key challenges include:

- Protocol Fragmentation: Machines use various incompatible protocols such as Modbus RTU, ISO on TCP (Siemens), and MC Protocol (Mitsubishi).

- Harsh Environments: Standard networking gear often fails due to extreme temperatures or unstable power supplies in factories.

- Data Overload: Uploading raw data from every sensor directly to the cloud consumes excessive bandwidth and causes latency.

2. The IG502 Solution

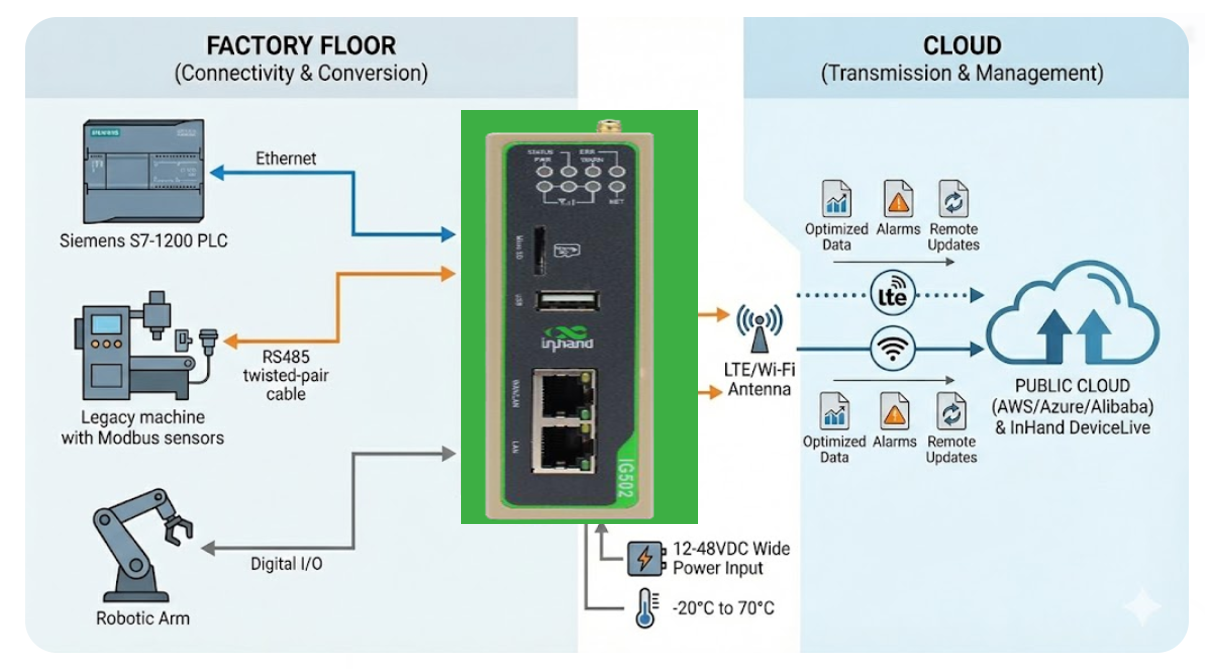

The IG502 serves as a high-performance edge computing gateway that bridges the gap between the factory floor and the cloud.

- Multi-Protocol Collection: Using the built-in DeviceSupervisor Agent (DSA), the IG502 can simultaneously collect data from 80+ mainstream industrial protocols.

- Edge Data Processing: Leveraging its ARM Cortex-A8 600MHz processor and Python programmability, the gateway performs local data filtering and smart analysis.

- Industrial-Grade Reliability: The hardware is built to withstand temperatures from -20°C to 70°C and supports a wide power input of 12-48VDC..

3. Implementation Workflow

Step | Action | IG502 Feature Utilized |

Connectivity | Connect Siemens S7-1200 PLCs via Ethernet and legacy Modbus sensors via RS485. | 2x 10/100Mbps Ethernet ports and RS485/RS232 interfaces. |

Conversion | Convert PLC and sensor data into standard formats using a "zero-code" approach. | DeviceSupervisor Agent (DSA) service. |

Intelligence | Run custom Python scripts to trigger local alarms if a machine's vibration exceeds safe limits. | Python secondary development platform. |

Transmission | Send optimized data to the corporate cloud via 4G LTE or Wi-Fi. | Global cellular access and Wi-Fi/Ethernet failover. |

Management | Remotely update gateway firmware or monitor connection status. | InHand DeviceLive and Device Manager cloud services |

4. Key Benefits

Reduced Connectivity Costs: Only meaningful, pre-processed data is sent to the cloud, significantly lowering cellular data usage.

Uninterrupted Monitoring: Dual SIM card failover and hardware "watchdogs" ensure the gateway remains online even during network or software glitches

Scalability: New machines or custom logic can be added remotely via the Docker management or Python app deployment features.

Topic Participants

david.jing